Panda-Box

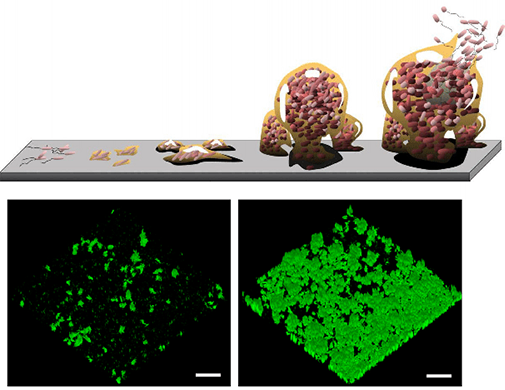

The Panda-Box biological reactor is a one-stop solution to wastewater pollution control in residential areas with low-to-medium population density. The Panda-Box occupies 50% less space than similar products in the global market, making it easier to ship, deploy, and operate wastewater treatment units in complex urban environments. This is made possible by Forigin's proprietary IFAS-Mox (Integrated Fixed-Film Activated Sludge Mox) biotechnology, which uses silicon-carbon microparticles as the main biocarrier in the central reaction space. By creating a gradient distribution of dissolved oxygen in the micro-environment, the Panda-Box enables the symbiotic coexistence of anaerobic, anoxic, and aerobic microorganisms, as well as the simultaneous removal of nitrogen and phosphorus. The Panda-Box can be digitally monitored and operated via the Phoenest intelligent monitoring system, which drastically simplifies inspection and maintenance procedures.

Application scenarios

Rural Household

Tourist Areas

Homestay

Villa Zone

Public Toilet

Border Post

Sea Ranches

Island

Product Advantages

Extremely stable micro-organisms highly resilient against system shocks. Forigin's micro-organisms can fully recover within 3 days even after extreme conditions (i.e. 6 months without wastewater input), does not produce any organic waste, and does not need any chemical treatment; digitally activated anti-bacterial disinfection system.

01

Smallest unit only requires < 0.9㎡ of space. Open design makes installation, operations, and maintenance simple and convenient.

02

Product lifespan > 30 years. Unit cased in 6th generation high polymer. Compact, strong, and anti-corrosion.

03

Unattended & automatic operations. Remote monitoring. Maintenance frequency: once per year.

04How It Works

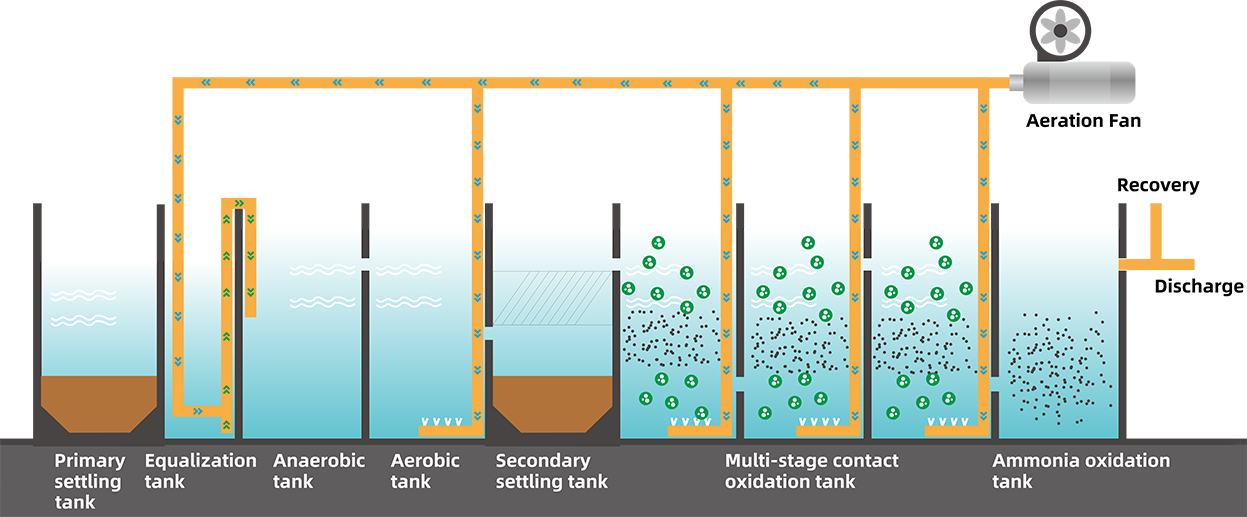

Wastewater enters the Panda-Box after septic tank pre-processing and passes through primary settling tank and equalization tank, where large particles are removed and water quality and quantity are adjusted to optimal levels. It then flows through the anoxic tank and aerobic tanks for biological treatment, and enters the secondary settling tank for initial mud-water separation. The resulting sludge returns to the aerobic tank, while the remaining supernatant enters the multi-stage contact oxidation tank, where biphasic biocarriers are deployed to remove organic matter and ammoniacal nitrogen, as well as decompose any residual sludge. The next stage is the ammonia oxidation tank, where the micro-environment is adjusted and carborundum microparticle biocarriers are deployed to facilitate the final stages of ammonia oxidation and phosphorus fixation. Finally, the water is sterilized by ozone before being discharged or reused.

Panda-Box Work Process Diagram

Micro-organisms Regulation Mechanism

Panda-Box Installation Diagram

Panda-Box Installation Rendering

Specifications and Models

| Model | Capacity(m³/d) | Installation Type | Size(m) | Operating Power(W) | Power Supply Mode |

|---|---|---|---|---|---|

| Panda-Box-500 | 0.5 | Above ground/underground | 1.2*0.6*1.2 | 25 | Two phase three wire 220V |

| Panda-Box-1500 | 1.5 | Above ground/underground | 1.8*0.9*1.5 | 55 | Two phase three wire 220V |

| Panda-Box-3000 | 3 | Above ground/underground | 2.4*1.2*1.8 | 110 | Two phase three wire 220V |

| Note: The effluent standard is Class I B/A standard in the “Discharge Standard for Pollutants from Urban Wastewater Treatment Plants” (GB18918-2002) | |||||